- Bakery Ingredient (Brown Breads, Rye, Gingerbread)

- Food additive (BBQ Sauce, Syrups)

- Brown Sugar

- Distillation of Rum

- Candy Making

- Animal Feed Supplement

- Yeast

- Citric Acid

- Ethanol Production

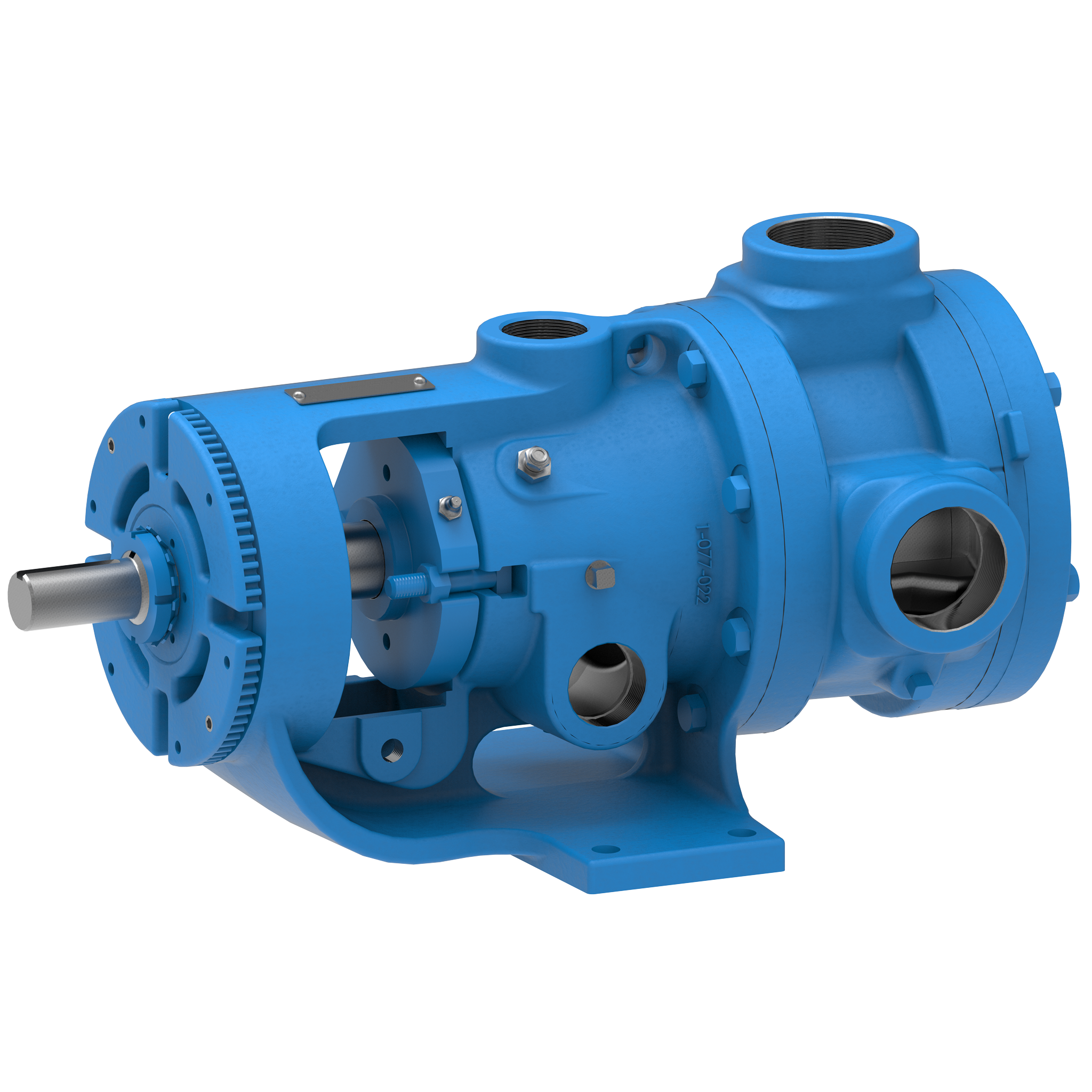

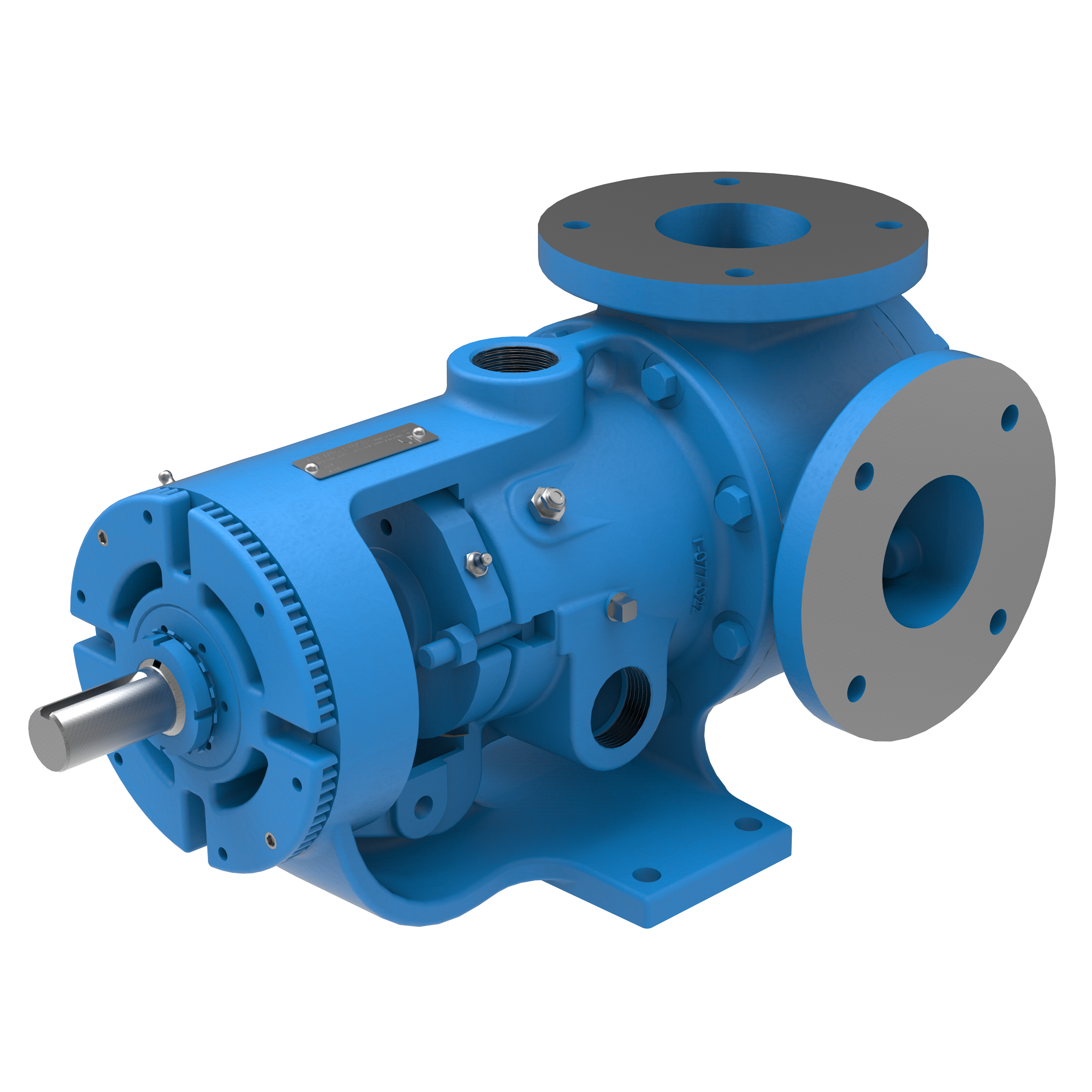

Viking pumps are used for pumping molasses at sugar cane and beet plants as well as downstream terminals, feed mills and food processors. A, B and C Molasses from cane / High & Low green syrup and Low Raw molasses from beet plants is what’s left after the sucrose has been extracted from the juice.

In sugar mills, Viking pumps are found downstream of the evaporators and are used to feed A & B molasses back into the process with C molasses going to storage tanks for transfer to railcars and pipelines. At terminals, feed mills and food processing plants, Viking pumps are used to unload rail cars and transfer product to storage tanks, tanker trucks and day tanks for use in the manufacturing of various products. Viking Pump’s robust & easy to maintain pumps will improve your operational efficiency.