- A Molasses (High Green Syrup)

- B Molasses (Low Green Syrup)

- Final Molasses (Blackstrap Molasses)

|

|

|

|

|

|

|

|

|

|

|

|

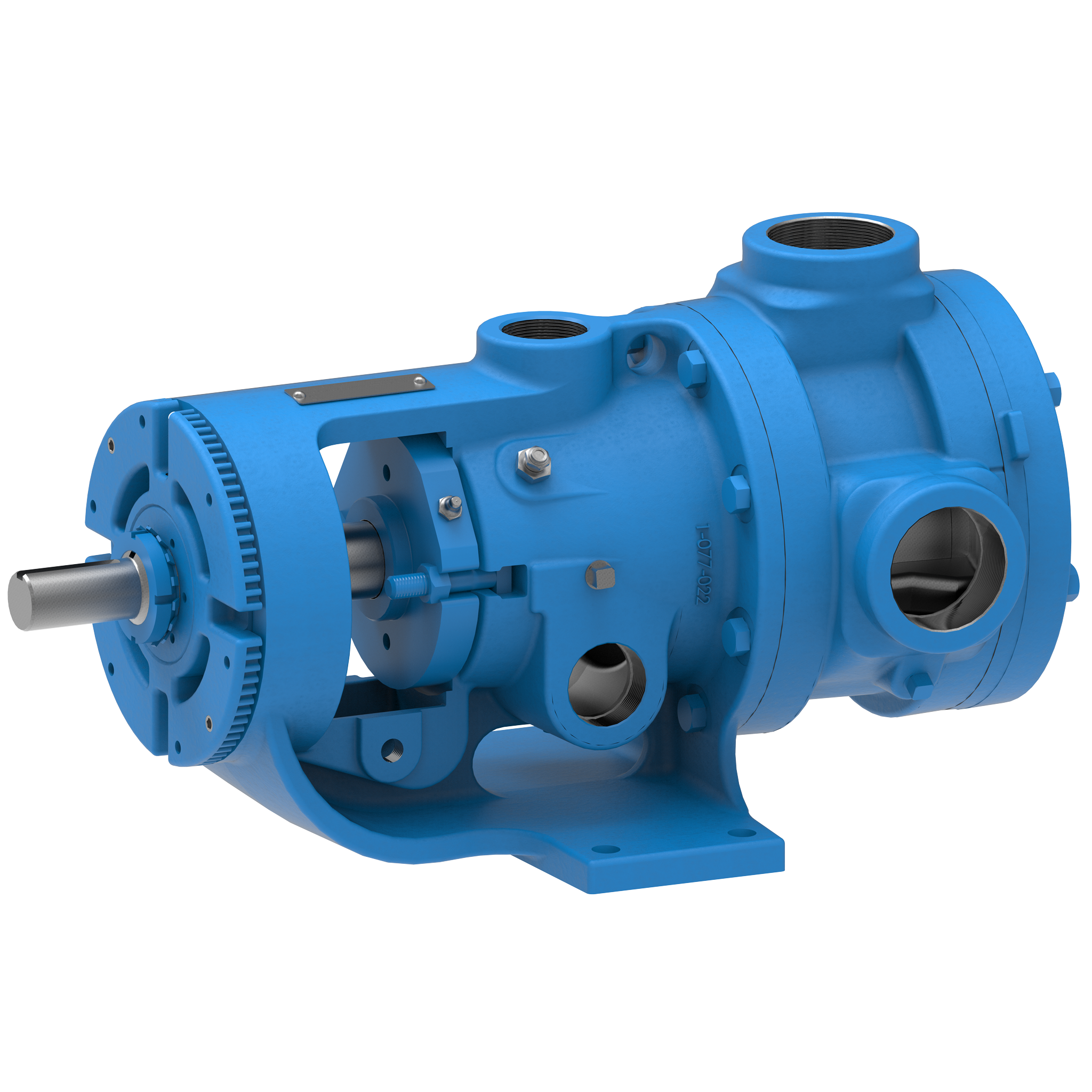

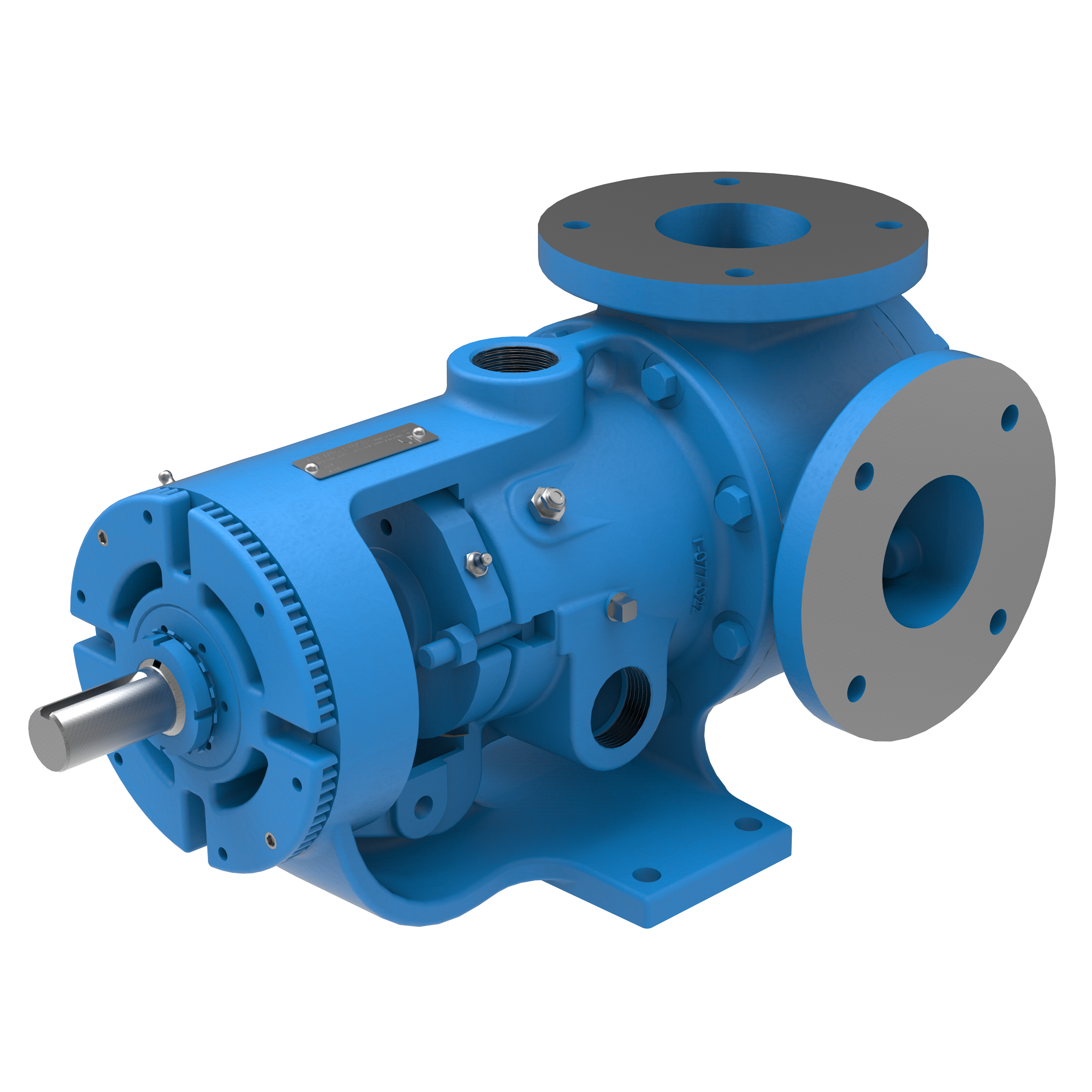

Viking pumps play an integral part in the production of sugar, transferring molasses and syrups throughout the process. Pumps in these applications see a range of viscosities based on the specific application. The last step in the process is the transfer of final molasses to storage tanks where it can be loaded onto rail cars, tanker trucks and even pipelines for distribution